Shelf racks

We offer shelf racks in versions for warehouses and storage of medium and heavy loads (heavy MR and HR racks) and light manual goods (SMK light racks). Warehouse shelf racks are also intended for use in wholesalers, archives, store back-up facilities, or companies selling goods online with manual packaging. As a manufacturer of metal warehouse racks, we are able to provide system racks for the storage of heavy loads and very high load capacity up to 5,600 kg per shelf, high-bay shelf racks up to 10 m high, as well as light shelf racks, when relatively light loads from 125 up to 375 kg per shelf are stored, e.g. documents in binders or small goods. Our offer of fixed frame racks is completed with tire racks. We offer a variety of shelf depths from 30 to 155 cm and the width of shelves in the range of 105 to 300 cm, so each customer will find among our products a professional warehouse shelf rack, exactly tailored to his needs and financial capabilities. All our warehouse racks are system products, they can be connected in series into single or double rack lines or they can be used to build multi-level warehouse mezzanines.

The solutions we use allow us to obtain up to 4 times larger storage space. System shelf racks that we provide can be very easily extended or disassembled and moved to another warehouse. The production also includes various accessories, shelves fillings and protection of shelves, goods and personnel. We supply shelf racks in both galvanized and powder coated versions in various RAL colours. The colours are agreed at the stage of preparing the technical design and commercial offer. All the shelves we offer are products for professional use, with the TUV certificate, which have been used for many years by thousands of companies in Poland. Their high quality has been recognized especially in sectors requiring high reliability, safety and durability. As a manufacturer of shelf racks, we are one of the few on the market able to offer our customers high quality at an affordable price.

Application

Easy access to all stored products and materials, such as: tools, car parts, food, cartons and packed products makes metal shelf racks an ideal choice for objects that focus on manual load handling on the rack. Such facilities include, among others:

- warehouses

- archive

- workshops

- wholesalers

- libraries

- backroom of shops

- catering facilities

Shelf racks are the simplest and most universal choice of customers. However, in our offer you will also find other specialized storage racks that can fulfil the storage tasks much better. These specialized warehouse racks include: archival racks, pallet racks, high bay racks and cantilever racks. Alternatively, if the customer expects fully comfortable manual access to the highest shelves of the rack, we can also provide storage mezzanines based on various types of shelf racks. The use of a storage mezzanine, instead of a shelf rack, allows you to completely eliminate the need for ladders by warehouse users.

Benefits

The biggest advantage of shelf racks is the possibility of installation in all types of warehouses, combined with low purchase costs. This is due to the universal design of the rack, which can be modified in any way at your own discretion.

Simple construction

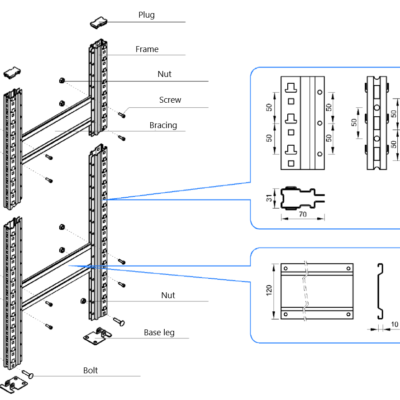

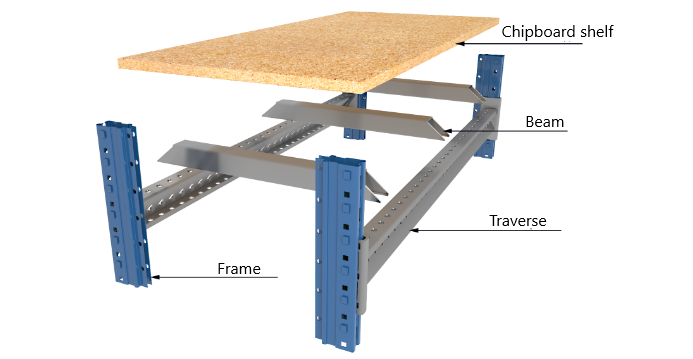

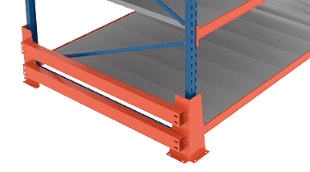

The components of the racks are:

- frame

- shelfs

- bracing (to provide stiffness for taller frames)

- anchors

- optional traverses

All of the above-mentioned elements have different sizes and recommended loads, that is why the selection of the appropriate rack should not be a problem.

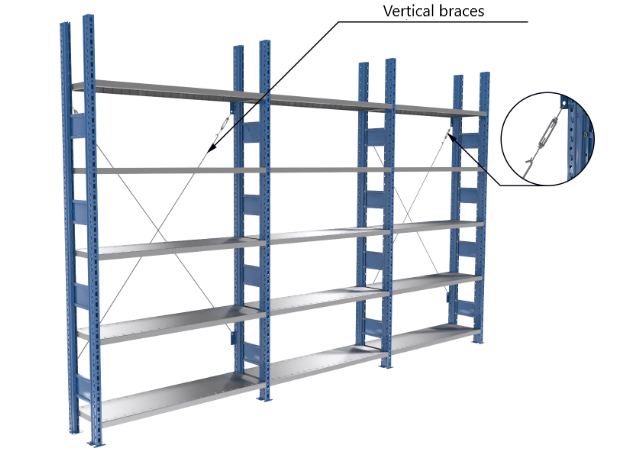

Shelf rack with vertical braces

Three variants

At the moment, we have 3 types of racks in our offer:

- lightweight shelving

- heavy duty shelving

- tyre shelving

Lightweight shelving

In our offer of warehouse racks you will find shelf racks for light loads, i.e. the SMK system. The SMK metal shelving system is also used in the case of warehouse mezzanines, where it is used as the main structural element of the shelf mezzanines. Despite the name “light”, this type of system rack can withstand loads of up to 5,000 kg per rack and up to 375 kg per shelf. It is possible thanks to the use of durable shelves and galvanized steel frames, the height of which can be up to 10 m.

Light shelf rack in sequence

Available dimensions of SMK light shelf racks:

- Frame height from 185 cm to 980 cm

- Shelving depth from 30 cm to 70 cm

- The width of the bookcase: 105 cm, 125 cm, 135 cm

- Perforation every 5 cm

- Maximum shelf load: 375 kg

- Maximum section load: 5000 kg

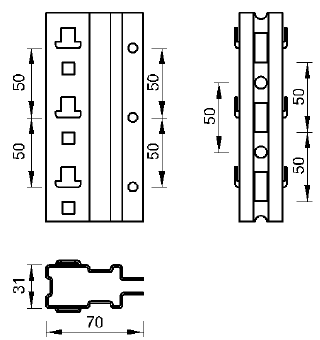

Structure feet and frames rack SMK

Construction of the frame of the SMK shelf rack

SMK shelf racks

SMK accessories

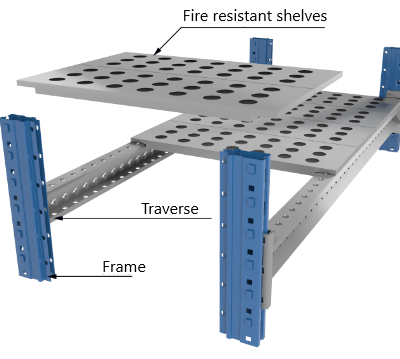

Fire protection shelf

The shelves in the fire-resistant version are used to store flammable materials. Thanks to their perforated structure and the use of reinforced steel, they have extended resistance to fire and allow water to move to the lower levels of the shelf rack during a fire. This gives more valuable time to extinguish a potential fire and increases the effectiveness of the extinguishing action.

Fire resistant shelves

Chipboard

Chipboard is used to store goods weighing up to 375 kg per shelf. It is possible thanks to special reinforced Z-beams and crossbeams.

Chipboard shelf

Shelf divisions

The divisions for the shelves of the warehouse shelves are used to sort separate types of products. They can be mounted on one side from the bottom of the shelf, or on both sides from the bottom and top. Shelf divisions are available in several different heights, e.g. 100 mm, 175 mm, 275 mm. They are made of light, thin sheet metal with a thickness of 1 mm, so they do not affect the maximum load capacity of the shelf and rack.

Graduations for shelf racks

Drawers

Drawers in shelf racks are used to store small, often expensive products that could be easily damaged by unintentionally pushing them off the shelf onto the floor. Drawers not only increase the comfort of use, but also offer additional usable space in relation to ordinary shelves (the possibility of using up to four drawers instead of one shelf). Products that are recommended to be stored in drawers include, for example, glass bottles and containers, electronic parts, computer components, cosmetics.

Shelf rack with drawers

Plastic containers

They perform a similar function to drawers – they conveniently store all the small items. However, they do this for a lower cost, at the cost of less space.

Plastic containers for shelf racks

Side bumpers

They are used to protect the racks against collision with forklifts or pallet trucks.

Side bumpers for shelf racks

Heavy shelf racks

The heavy shelf racks include the MR and HR series, which are also used in integration racks. Thanks to the use of thicker profiles and crossbeams for the installation of shelves, these systems can carry much greater loads. The lifting capacity for the MR system is up to 5,000 kg per section and up to 960 kg per level (shelf). The HR system can carry even greater loads, the weight of which can be up to 16,200 kg per section and up to 5,600 kg per level (shelf). Heavy shelf racks in the HR and MR system can be easily converted into integrated racks or storage mezzanines, which gives them a high level of personalization and facilitates possible subsequent sale. An additional advantage of heavy shelf racks is the possibility of storing pallets on crossbeams, which normally form the basis for the shelves. Thanks to this, we can store loose and palletized products together.

Heavy shelf rack in the HR system

Standard dimensions of the MR system

Rack (profile) height:

2200 mm; 2600 mm; 3000 mm; 3600 mm; 4500 mm; 5000 mm

Rack length modules in the light between the legs:

1250 mm; 1330 mm; 2000 mm; 2500 mm; 2660 mm; 2730 mm; 3000 mm

Shelf depth:

600 mm; 700 mm; 800 mm; 950 mm; 1150 mm; 1350 mm; 1,550 mm

Maximum load per frame:

5000 kg

Maximum load per shelf / level:

960 kg

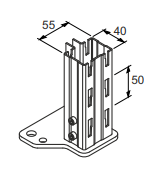

Foot dimensions:

Width -> 55 mm

Length -> 40 mm

Perforation every 50 mm

Base leg for MR shelf racks

Heavy duty shelf rack HR

Standard dimensions of the HR system

Rack (profile) height:

2000 mm; 2500 mm; 3000 mm; 3600 mm; 4500 mm; 5100 mm; 5500 mm

Rack length modules in the light between the legs:

1250 mm; 1330 mm; 2000 mm; 2500 mm; 2660 mm; 2730 mm; 3000 mm

Shelf depth:

850 mm; 1050 mm; 1150 mm

Maximum load per frame:

16,200 kg

Maximum load per shelf / level:

5,600 kg

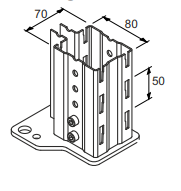

Foot dimensions:

Width -> 70 mm

Length -> 80 mm

Perforation every 50 mm

Base leg for HR shelf racks

MR shelf racks

HR shelf racks in a small warehouse

Heavy duty shelf racks accessories

Transverse beams under the slab

Used to store products along the crossbeams on a shelf rack (e.g. long bars or boards). Crossbars can also be used to hold pallets smaller than standard Euro-pallets. Additionally, plywood boards can be placed on them to form a floor for storing loose boxes, cartons, tools, etc.

Crossbeam for crossbeams in the HR, MR system

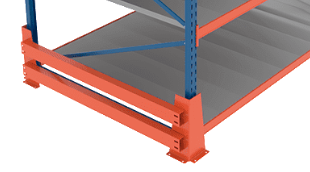

Frame bumpers

Bumpers protect the feet of the pallet rack from accidental impacts by forklifts. In the event of such a collision, without the use of protection, it is likely that the entire line of the storage rack will be overturned, resulting in huge losses. Therefore, for each warehouse with forklifts or other vehicles moving in the aisles, it is recommended to purchase bumpers. It is much more rational to replace one damaged bumper than to risk the entire rack line with the goods.

Front bumper in RAL 2008 color

Side bumper

The largest type of bumper that protects the entire side of the frame of the pallet rack. It consists of two corner bumpers and additional beams, providing the highest level of protection of the frame against accidental collisions. There are two variants of this bumper: for one frame, for two frames (with two pallet racks facing each other).

Side bumper for a pallet rack

Shelves – smooth

They fill the space between the traverses, allowing for convenient storage of general cargo. They practically transform a pallet rack segment into a larger shelf rack with increased load capacity. This solution is recommended for traverses with low lifting capacity, because then we do not waste the potential of traverses with a high maximum lifting capacity.

Dimensions available:

Depth: 744 mm, 844 mm, 944 mm, 1044 mm

Width: 187mm, 226mm

Thickness: 1mm, 1.5mm

Smooth shelves for a pallet rack

Platform made of platform grating

Mesh shelves enable the storage of both loose and palletized products. Despite their mesh structure, they are very durable and provide a high level of fire safety. They allow the free flow of liquid, so that during a fire, the water flowing from the top will get to the lower storeys of the rack, increasing the chances of extinguishing.

HR shelf racks with a platform grating

Chipboard shelves

The solid chipboard placed on the crossbeams acts as a cheaper alternative to ordinary shelves, which is also much easier to replace in case of damage or dirt.

HR shelf racks with chipboard

Slanted shelves

Special shelves on which chipboards with products are placed or, for example, roof tiles to display the goods.

HR shelf racks with slanting shelves for displaying goods

Custom shelves

Shelves prepared especially for customers’ orders allow for arranging any exhibition. Due to the nature of such shelves, the final step of the “customization” process takes place during assembly. The materials necessary to finish such a shelf must be provided by the customer or agreed upon when placing the order.

MR shelf racks with a personalized shelf for bathroom display

Quality and safety

The use of the highest quality steel and high production standards have resulted in the fact that our racks have obtained the German TUV certificate, which proves the professional manufacture of our shelf racks.

Full service

Feel free to contact us for individual pricing and warehouse design for pallet racks. For larger orders from the factory, we offer a color selection of individual elements from the entire RAL palette.

Financing

We provide attractive financing of shelf racks in the form of leasing. You do not need your own funds to finance the investment.

Transport

We organize the transport of shelf racks to any place in Poland and the EU.

Frequently asked questions

The shelf mezzanine is best used in warehouses with a large amount of stored goods, where comfortable access to shelves is recommended, i.e. easy access at the employee’s fingertips, without the need to use additional ladders or pedestals. This most often occurs in the case of a high rotation of goods, when the activities of picking articles from the shelves are performed very often, e.g. daily packaging of goods for shipments. Another indication for the use of a mezzanine is the desire to maximize the use of the available space at the full height of the warehouse, because the floor of the warehouse mezzanine is designed and used on several levels.

Shelf racks are a better choice when we store smaller amounts of goods and we only need one usable level. Racks are also a rational solution when we reach for items on shelves relatively rarely, e.g. for documents in binders.

It depends on what the maximum load per shelf we want to achieve. SMK type racks can load a maximum of 375 kg per shelf, while MR and HR have a maximum load of 960 kg (MR) – 5600 kg (HR) per shelf.

The maximum height of the shelf rack is:

- SMK – 980 cm

- MR – 500 cm

- HR – 550 cm

The maximum width of the shelf for SMK is 135 cm, and the maximum depth is 70 cm. In the case of MR racks, the maximum width is 300 cm and the depth is 155 cm. For the HR system, the maximum width is 300 cm and the depth is 115 cm.

Racks for professional use are made of thick steel profiles, do not require mounting to the wall, they are very stable. They can be used to build structures up to 10 m high and in any case can be easily transformed into multi-level storage mezzanines. They have a variety of accessories that allow you to additionally increase their functionality. “Professional” shelves have technical tests and safety certificates like TUV.

“Market” shelves are made of very thin sheet metal (often not steel) with low resistance to bending. Very often, the condition for their use is to attach them to the wall, which only allows them to be loaded. They have very low safety factors and are only suitable for “home” applications when the structure is low and we do not store valuable or dangerous items on shelves. They often have an overestimated load capacity and after their suggested nominal load, the rack begins to deform and bend. They cannot be upgraded. It is also not possible to build a warehouse mezzanine on their basis.

Yes, it is possible, but you will need to insert special profiles that will be responsible for supporting the weight of the mezzanine. This is required because the shelf racks alone cannot support the weight of the structure.

Thanks to the use of 50mm perforation, changing the position of the shelf is simple and convenient. This operation can be performed by virtually anyone, because the shelves are pressed in.

It is possible, but it is not recommended. This is because the shelf racks are to be lightweight and are made of (compared to pallet racks) thin sheet metal. In the event of strong winds, these racks could simply tip over. The exceptions to this rule are the placement of the shelf racks outside against walls that would act as the back. However, it involves the additional cost of making them resistant to external conditions, by covering them with hot-dip galvanization.