Pallet racks

Pallet racks are the optimal solution for facilities where goods are stored mainly on pallets. As a large manufacturer of pallet racks, Kifato can offer you a variety of frame and beam solutions at an attractive price, which will maximize the use of the available space. A wide range of security and accessories allows you to personalize the equipment of each warehouse. We advise, design and estimate. We select pallet racks for specific needs, existing loads and types of stored products and pallets. Thanks to the use of additional accessories, such as crossbeam trusses, it is also possible to store non-standard pallets or loose goods. Installing specialized accessories for the storage rack, e.g. a securing net, frame bumpers, allows you to increase the level of safety of employees and stored goods.

External pallet racks

Pallet racks – for every warehouse

Due to low purchase and assembly costs, reliability, versatility and a high level of personalization, the pallet racks from the manufacturer Kifato are used in many types of warehouses, including in the following facilities:

– with a loose load (chests, boxes, foil-wrapped products);

– intended for the storage of pallets with various loads;

– where order picking takes place directly from the pallet;

– where easy access to palletized products is a priority;

– where maximum use of the available space is needed.

Such facilities include, among others:

– Building depots

– Logistics centers

– Central warehouses

High storage pallet racks

Pallet racks – advantages

– universal construction enabling the storage of a wide range of various products;

– use of high-quality steel for production and the highest standard of workmanship;

– effective use of storage space;

– easy inventory control;

– possibility of combining with shop shelves in order to obtain an integrated shelving.

Pallet racks – wall-mounted with beams for segregation

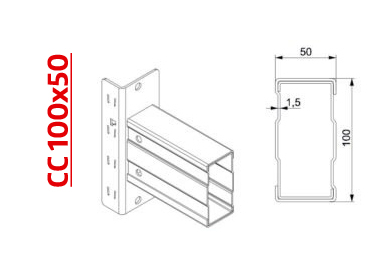

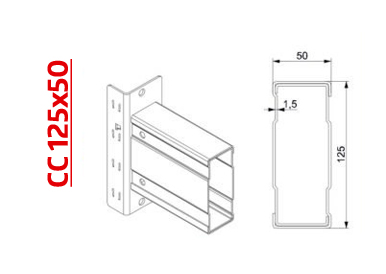

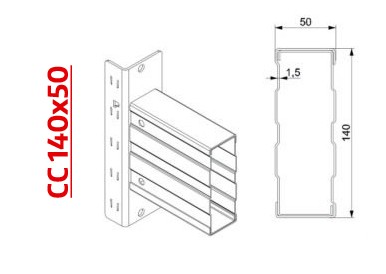

Construction

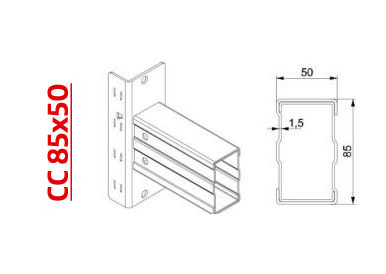

Pallet racks consist of 3 main components:

- Profiles – the only element of the rack that has direct contact with the ground. Pallet rack profiles should be placed on a hard, solid surface to ensure the highest possible stability of the structure. The profiles have perforations every 50mm, allowing for convenient configuration of the traverses.

- Bracing – an element connecting two profiles to create a rack frame. Bracing stiffens the structure

- Traverses – they bear the entire load of the stored products. They also connect the frames with each other, creating a rack line.

Pallet racks during assembly

Items available immediately

The main components of a pallet rack are:

Traverses

Length: 1850 mm, 2700 mm

Max load per level: 1200 kg

Length: 1850 mm, 2700 mm

Max load per level: 2100 kg

Length: 1850 mm, 2700 mm

Max load per level: 3000 kg

Length: 1850 mm, 2700 mm

Max load per level: 3600 kg

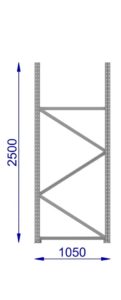

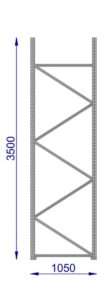

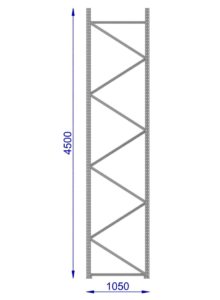

Frames

The stated maximum load on the frame is defined for a seat height of 1500 mm and a minimum of four racks in a row. In the case of a smaller number of racks, frame load reduction factors should be used:

- for three sections in a row – 0.88;

- for two sections – 0.77;

- for one section – 0.66.

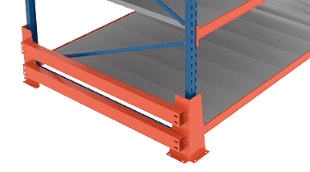

Outdoor racks

Pallet racks can be installed externally, but this involves additional costs. These costs result from the need to cover the racks with hot-dip zinc, which provides protection against external conditions. Another factor to keep an eye on is the ground, external racks need to be attached to a hard ground like concrete. Paving stones are not suitable for this task and a bookcase placed on such a cube will simply tip over. It is good to put external racks in longer rows. or place them with their backs to each other, this increases stability and allows for the storage of larger loads. We do not install roofs for pallet racks, as additional loads from the roof (e.g. snow) may cause the rack to collapse if the load buffer is not maintained.

External pallet racks – wall-mounted

A wide range of accessories

Additional elements of the pallet rack that improve its functioning or provide additional security are:

Frame bumpers

Bumpers protect the feet of the pallet rack from accidental impacts by forklifts. In the event of such a collision, without the use of protection, it is likely that the entire line of the storage rack will be overturned, resulting in huge losses. Therefore, for each warehouse with forklifts or other vehicles moving in the aisles, it is recommended to purchase bumpers. It is much more rational to replace one damaged bumper than to risk the entire rack line with the goods.

Front bumper in RAL 2008 color

Front bumpers

They are used to cover the front of the pallet rack frame leg. Thanks to their narrow structure, they do not obstruct access for pallets to the ground floor of the rack. They can be used as corner bumpers, but it is not recommended.

Front bumper for pallet racks

Corner bumpers

Reinforced counterpart of the front bumper, protecting the corners of the pallet rack legs. By increasing the thickness of the sheet and removing one side, we increase the strength while maintaining a similar price to the predecessor.

Corner bumper for a pallet rack

Side bumper

The largest type of bumper that protects the entire side of the frame of the pallet rack. It consists of two corner bumpers and additional beams, providing the highest level of protection of the frame against accidental collisions. There are two variants of this bumper: for one frame, for two frames (with two pallet racks facing each other).

Side bumper for a pallet rack

Horizontal and vertical braces

They are used in the case of high frames of storage racks. They stiffen the structure and make it possible to put the rack up without the need to mount it to the wall. They can be mounted to lower frames, but their main use is in pallet racks over 4.5 meters high.

Horizontal braces for sewing a pallet rack

Trusses on traverses

The trusses enable the storage of loose assortment such as: boxes, packs, cartons, etc. on a pallet rack. It should be remembered that placing pallets on the lattice is not recommended as it will lead to its destruction.

Trusses mounted on traverses

Crossbeams

Used to store products along the crossbeams on a pallet rack (e.g. long bars or boards), they can also be used to hold pallets smaller than standard Euro pallets. Additionally, plywood boards can be placed on them to form a floor for storing loose boxes, cartons, tools, etc.

Crossbeam

Crossbeams for pallets

The product is very similar to the crossbeams under the slab, but with two important changes:

- The sheet thickness has been increased in order to effortlessly support the weight of the loaded pallet

- The beam is flush with the traverse to allow easy loading / unloading with a forklift

The advantage of using crossbeams for pallets is the possibility of changing the orientation of the pallet storage and better weight distribution on the crossbeam.

Crossbeams for the storage of pallets for warehouse racks

Safety net

It guarantees that the stored materials will not fall out from the back or the side of the pallet rack. This provides additional security for warehouse operation. Employees can be sure that no product will fall on them accidentally, e.g. as a result of pushing the goods during loading or other operating errors.

Safety net on the side of the pallet rack

Protection of traverses

They secure the traverse in place and prevent it from moving, thus providing protection against accidental sliding out. They are a standard accessory attached to each purchase and valuation of pallet racks in our company. The traverses can be installed without them, however it is recommended only to test the optimal arrangement of the levels.

Protection of the crossbeam for KI storage racks

Pallet stops

Their purpose is to protect the pallet against accidental falling off the traverses. They are mainly mounted on the side opposite to the loading direction, but it is possible to place such a stop on both sides. It gives us 100% certainty that the pallet will not fall, and thanks to the easy assembly / disassembly, we can quickly block / unblock the pallets.

Pallet stopper for KI storage racks

Tubular separator

It is intended mainly for the lowest levels of a pallet rack, serving as a tool for sorting individual types of products. As shown in the photo, it is best for sorting logs (such as pipes, boards, boards etc.) placed vertically.

Tube bumpers for storage racks

Leveling pads under the feet

A very simple accessory that allows you to even out any unevenness in a pallet rack. By adding pads, we can guarantee that the construction level is maintained.

Leveling pads under the feet for KI warehouse racks

Shelves – smooth

They fill the space between the traverses, allowing for convenient storage of general cargo. They practically transform a pallet rack segment into a larger shelf rack with increased load capacity. This solution is recommended for traverses with low lifting capacity, because then we do not waste the potential of traverses with a high maximum lifting capacity.

Dimensions available:

Depth: 744 mm, 844 mm, 944 mm, 1044 mm

Width: 187mm, 226mm

Thickness: 1mm, 1.5mm

Smooth shelves for a pallet rack

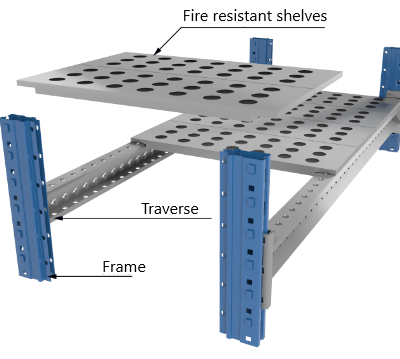

Fire protection shelf

The shelves in the fire-resistant version are used to store flammable materials. Thanks to their perforated structure and the use of reinforced steel, they have extended resistance to fire and allow water to move to the lower levels of the shelf rack during a fire. This gives more valuable time to extinguish a potential fire and increases the effectiveness of the extinguishing action.

Dimensions available:

Depth: 744 mm, 844 mm, 944 mm, 1044 mm

Width: 187mm, 226mm

Thickness: 1mm, 1.5mm

Fire resistant shelves

Pallet racks – the highest standard

All our storage racks meet the formal requirements in terms of health and safety, fire protection. and building regulations. As a manufacturer of pallet racks, we guarantee the highest quality of workmanship and the safety of our racks confirmed by the German TUV certificate.

Pallet racks – variants

Row racks, otherwise known as pallet racks, are the most frequently chosen type of warehouse racks due to their simple and universal structure. In practice, row racks can perform a function similar to cantilever racks and shelf racks. This can be achieved by adding appropriate accessories that can be replaced or removed at any time. Of course, they will not be as good at fulfilling the functions of these more specialized counterparts, but for warehouses that constantly change the type of materials stored, pallet racking will be the perfect choice.

Row racks for the storage of mixed products

A system that uses the force of gravity to transport the stored pallets down the rack. The first pallet is also loaded with the first pallet for unloading. This is the so-called (FIFO) First in First Out system. The perfect technical solution for pallets with products with a short shelf life. The entire length of the rack can theoretically be unlimited, but due to the inclination of the first tier, the available floor space will be small. Therefore, part of the space under the shelf will be unusable, despite the free space.

Gravity flow racks

The push back system allows you to store up to 4 pallets deep at a time. Thanks to the use of rollers, taking them out is not a major problem. The system is ideal for medium-heavy materials. A forklift is needed to load and unload the rack.

Push back pallet racks

Drive-in racks operate on a similar principle to flow racks. The only difference is the Last In First Out (LIFO) system. The last pallet loaded comes out first.

Drive in Pallet Racking

Mobile pallet racks allow for the maximum use of the available space through the complete elimination of working tunnels. Using a remote control, the operator can place a specific pallet in the right place for pickup with a forklift truck. The mobile racking solution is especially useful where the costs of storage space are very high, e.g. freezers.

Mobile pallet racks

Full service

Feel free to contact us for individual pricing and warehouse design for pallet racks. For larger orders from the factory, we offer a color selection of individual elements from the entire RAL palette.

Transport

We organize the transport of pallet racks to any place in Poland and the EU.

Financing

We provide attractive financing of pallet racks in the form of leasing. You do not need your own funds to finance the investment.

Frequently asked questions

Due to the use of 50 mm perforation, the position of the traverses can be easily modified by the user. However, it should be borne in mind that the changes in the position of the crossbeams should be consistent with the indications of the technical documentation describing the pallet rack, provided to the customer by the supplier along with the goods.

It is possible, but the traverses should be fitted with special claws on which we can place the plywood floor. The rack retains its maximum load capacity and additionally allows you to store any product.

Pallet racks require the use of an industrial floor with an appropriate class of strength, stiffness, leveling and flatness. For safety reasons, it is not allowed to install the racks on cobblestones or asphalt.

Yes, and it’s a really simple operation with our pallet racking. It is enough to place the racks at the appropriate distance and then install the floor and stairs. In some places, it may be necessary to add additional poles to install all elements (e.g. at stairs).

It depends on the height of the pallet racks.

- Low pallet racks up to 350 cm, can be installed by two people alone, as it definitely facilitates the process. Just follow the instructions attached to the racks.

- For pallet racks higher than 350 cm, we recommend our professional assembly or another proven external company. This will not only shorten the assembly time, but also guarantee a solid “assembly” of the structure and safety of use.

The exception are outdoor shelving, which in any case should be assembled by trained fitters.

Pallet racks are better suited for warehouses where only palletized products are stored, because they provide greater load capacity and have larger dimensions (height, width and depth). Integration shelves, on the other hand, are suitable for warehouses and stores, where both storage and sale of mixed products takes place (general cargo, oversized products and on pallets).

Due to their simple structure, pallet racks are cheaper and easier to modify, and thanks to a wide range of accessories, they should meet the requirements of most warehouses. On the other hand, integrated shelves provide a greater level of customization and can be considered a universal solution, but it is more expensive to buy.