Mezzanine floors

Mezzanine floors are an advanced technical solution that allows you to quickly expand the available warehouse or work space by adding an additional level or several levels of storage. Storage at an additional level usually takes place on pallets or shelf racks. You can also meet the use of industrial mezzanines with one level of storage of names such as warehouse platforms. In each case, this means additional usable space to be used by the investor, tailored exactly to his specific needs. Industrial mezzanines can be used both for storing goods and their packaging, but also as a place for additional, dedicated workstations. It is worth noting that the assembly of a warehouse mezzanine is much cheaper than the construction or extension of a warehouse with the same area. The limited number of formalities and the shortened process of implementing an industrial mezzanine are also important, compared to the classic construction of a warehouse – which in many cases is of key importance for the future user.

Warehouse mezzanine – hall with stairs

Usage

The ideal environment for mezzanine floors are warehouses, where:

- The pallets and general cargo are stored simultaneously

- The construction of the hall does not allow the assembly of pallet racks

- The user wants to improve processes in the company

- There is not enough space for storage

- The building is relatively tall

- There is confectioning or packing of the goods

- You need to make the most of the available space

- The investor cares about the short lead time

- The cost of a warehouse space is relatively high It is not possible to expand the warehouse

- The investor cares about the flexibility of solutions, e.g. it assumes future changes in the mezzanine structure along with the development of its business

The use of industrial mezzanines may change depending on their configuration. For example, a mezzanine equipped with shelf racks is ideal for storing various small items on the ground floor and higher levels. As a rule, this type of mezzanine also has lower requirements in terms of the maximum load capacity of the structure.

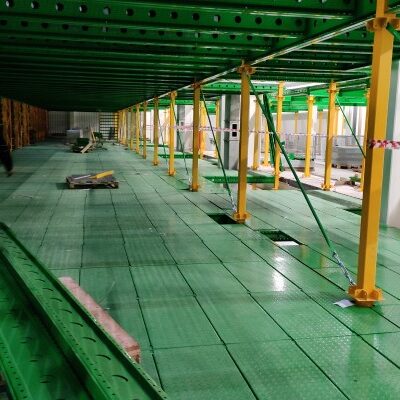

Multilevel mezzanine floor in MR system

Benefits

- Advantages Maximum use of available space

- Much shorter implementation time compared to classic warehouse construction

- High level of personalization – a “tailor-made” solution Durable and safe construction of an industrial mezzanine

- A project made especially for you

- Simplicity in assembly and disassembly, allows easy transfer to another warehouse

- Several possible proven variants to choose from

- Even several storage levels possible

- Effortless installation of lighting, fire protection systems, compressed air, cameras, etc. along the entire length of the mezzanine thanks to openings in the girders

- Accessories: drawers, nets, lighting, sprinklers

- High load capacity of the mezzanine

- Fulfilment of health and safety standards, fire protection and building regulations

- Full freedom in terms of configuration changes or expansion

- Possibility to separate independent functional zones: storage, picking, packing

- Much lower costs than in the case of building a new warehouse or extending an existing one

- Increasing the value of a warehouse property

- Even several times larger usable area of the warehouse

- Possibility to create additional work stations located on the mezzanine

- Price directly from the mezzanine manufacturer

Pallet storage mezzanine

Proven design

Mezzanine floors differ in construction depending on how we want to use the ground floor and subsequent levels. The mezzanine ground floor may consist of:

- Shelf rack

- Pallet rack

- Create a completely free space based on the supports only – if you plan, for example, to store vehicles or production equipment there.

The supporting structure in each case are special supports that enable the installation of a higher level. Shelves can be installed on the mezzanine platform, or the space is used for pallet storage. A construction consisting of several levels is also possible. In each case, the structure of the warehouse mezzanine is designed and verified by designers to make sure that it will be able to support the weight of the stored products.

Storage mezzanine with a safety net

Industrial mezzanine corridor

The top floor of the warehouse mezzanine – the roof

Floor filings

In the mezzanine floors, we can choose five types of floors that can be combined to use the best features of each of them.

Smooth floor

It is the cheapest floor available, used as a base for mezzanine racks. Despite the attractive price, it is not recommended as a floor for usable space used by employees. This is because it does not protect against slipping, leaving staff vulnerable to fall injuries.

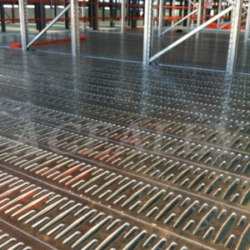

Non-slip floor

The non-slip floor is the most popular type of floor used in warehouse mezzanines. Prevents staff from slipping by providing a stable surface to walk on. Perforated floor Twin type for non-slip floors. It provides even better grip, giving the possibility to attach cables, lights or cameras.

Perforated floor

Twin type for non-slip floors. It provides even better grip, giving the possibility to attach cables, lights or cameras.

Chipboard floor

Provides a solid base that is difficult to slip on, but is susceptible to moisture that can destroy the board over time. Also, cleaning a dirty chipboard can be problematic. Therefore, the recommended use of this type of floor in the case of an industrial mezzanine is only in cases where there is no storage of liquid substances, in particular caustic substances.

Grid floor

It is useful when we want the mezzanine to be more “open”. This facilitates orientation in its structure and the content stored on it. Advantages include better lighting and air access to the products. Despite these bonuses, it should be remembered that small materials can pass through the mesh of the grate to the lower floors. Therefore, this type of flooring is best used in storage mezzanines, intended for the storage of products larger than the size of the planned mesh.

Perforated floor for storage mezzanine

Floor grating for industrial mezzanine

Non-slip floor for a warehouse mezzanine

Chipboard floor for storage mezzanine

Smooth metal floor for a storage mezzanine

For medium and high loads

The three most popular variants of warehouse mezzanines are:

-

Mezzanine floors for medium loads

The use of shelf racks as the basis of the structure limits its maximum load capacity, but allows for a reduction in investment costs and zero-level storage of small items. Solutions based on shelf racks are very popular in the case of e-commerce companies, but also those operating in traditional sales channels, where goods are picked for customers. Shelf mezzanines are made of galvanized steel by default.

-

Mezzanine floors for heavy loads

Pallet racks used as a base ensure a high level of stability and provide the highest level of lifting capacity. This allows the pallets to be stored on the rack’s crossbeams and on the floor. In addition, the assembly of several levels equipped with shelf racks is no longer a problem. The maximum permissible load for this type of mezzanine is 2000 kg / m². All elements can be painted in any colour from the RAL palette. The default colours are blue frames and orange traverses.

-

Storage platforms

They are based solely on pillars that support the entire weight of the structure. This allows for any arrangement of the platform, both on the ground floor and on the first floor. On level zero, you can easily store cars, heavy machinery, or even set up a small workshop. On the first floor of the storage platform, racks can be placed on which the parts required for the planned activities will be located. One of the options is the possibility of using the entire platform as a frame for an exhibition, e.g. for an exemplary home decor, or as an office. In the case of a warehouse platform, the only thing that limits the customer is his imagination. There are also extensive solutions with more than one utility floor. All construction elements can be painted in any color from the RAL palette. The default colours are blue frames and orange traverses.

Shelf storage mezzanine floor in the SMK system

Storage mezzanine – shelf for high storage

Universal storage mezzanine for any type of building

Warehouse mezzanine used to create an office in a warehouse hall

Accessories

Standard stairs to the storage mezzanine

Stairs to storage mezzanines

They meet all construction standards required for this type of structures. The stairs are made of durable metal, shaped in a way that gives the steps anti-slip properties. Additionally, in the case of high mezzanines, we install stairs equipped with a landing to increase the comfort of use.

Rocker gate for warehouse mezzanine

Mezzanine floors gates

A useful accessory when you plan to load products on a pallet from the side of the platform on level one and above. The gates can be divided into three types: pallet, rocker (tilting), sliding and double-leaf. The first type, i.e. rocker gates, allow for a completely safe pallet loading process, during which the operator is not at any time exposed to falling out of the industrial mezzanine.

Storage mezzanine with the ground floor secured with a net

Protective mesh

It has a simple function of protecting products against falling out of the mezzanine. The protective mesh also allows to cut off unwanted access for unauthorized personnel to valuable or potentially hazardous goods.

Tubular safety rails for the storage mezzanine

Safety barriers

The simplest form of protection against accidental falls for employees on a mezzanine. It is treated as a standard element of equipment, but it is possible to choose its different types, such as e.g. high barriers with a net providing an additional layer of safety.

Shelf racks with drawers for the storage mezzanine

Drawers

They are used for storing small products that could be easily damaged by accidental pushing off the shelf to the ground. Drawers also increase the comfort of use and the available usable space of the mezzanine in relation to ordinary shelves (up to 4 times more space). Such products may include, for example, bulbs in packaging, bottles, computer components (graphics cards, processors).

Sample lighting of the industrial mezzanine corridor

Lighting

In the case of the construction of warehouse mezzanines with many levels and a high density of shelves, natural light becomes insufficient. In this case, artificial lighting and cable ducts should be installed. Lighting installation should be agreed at the project level.

Security door to the storage mezzanine

Door

Their purpose is to prevent unauthorized personnel from accessing the mezzanine or its individual segments.

Loading elevator to the warehouse mezzanine

Lift

Thanks to its use, we eliminate the need to use forklifts for loading on the mezzanine floors of the warehouse. The elevator allows you to transport loose and lighted products with the use of “pallet jacks”.

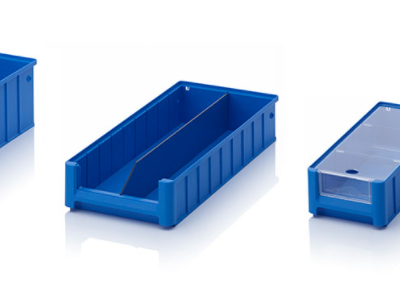

Containers for shelves for storage mezzanines

Plastic containers for storage mezzanines

Containers

Special containers made of plastic or metal for mounting on shelves allow for convenient segregation of small products without the need to install drawers. Sorting containers are a cheaper alternative to drawers, the cost of which is much higher. The wide available offer allows you to choose a container tailored to the specific needs of the customer and to optimize the method of storing the goods at an acceptable price.

Financial profitability

Mezzanine floors, thanks to their unique design, allow for a quick expansion of the usable space, up to 5 times cheaper than in the case of the construction of a new warehouse. This means that the investment in the mezzanine provides savings of 80% of the potential expenses for the construction of a new warehouse with the same quality of space. Thanks to such low investment costs, in relation to the benefits obtained, we obtain very high rates of return, the actual period of which is from one to two years. In addition, the assembly of an industrial mezzanine takes from a few to several days, which means that the user can generate additional income in a very short time by using a new, full-value space, while the construction of a new warehouse is a process that can take up to two years. Bearing in mind the above, it should be assessed that the investment in the mezzanine is certainly one of the best investment expenses of logistics or production companies.

Storage mezzanine in use

Free design

We offer a free warehouse mezzanine design after sending the technical data and dimensions of the building.

In order to design a warehouse mezzanine, we will need the following information:

- Building dimensions (room plan best)

- Type of floor

- Preferred dimensions of the mezzanine

- Number of levels

- Preferred type of mezzanine floor

- Number of stairs

- The width of the aisles and passages between the racks

- Pallet delivery method

- Preferred gateway for loading

- Load per level Specification of shelf / pallet racks

- Will you need drawers

- Destiny

- The colour of the elements

- Types of preferred security

- Will artificial lighting be needed?

During the preparation of the warehouse mezzanine design, attention should be paid to:

- Safety of the mezzanine structure. ⇒ Kifato uses the current ISO standards and FEM association guidelines.

- Compliance with health and safety and fire protection regulations. ⇒ The project is consulted with PPOZ and OHS inspectors. Escape routes, width of passages, railings, stairs, landings, skirting boards are selected in accordance with applicable regulations.

- Selection of the appropriate supporting structure. ⇒ Designers select the load capacity of the structure and shelves exactly to the needs. The structure has the required load capacity and the appropriate safety factor for the given application.

- Solutions for the transport of goods to and from the mezzanine. ⇒ A comprehensive mezzanine design includes well-thought-out solutions in the field of stairs, pallet gates, goods lifts and conveyors.

- The way of arranging the mezzanine in the existing building. ⇒ The design of the mezzanine should take into account the existing transport routes in the hall, temporary storage places and technical parameters of the used transport trolleys.

Warehouse mezzanine roof

Quality and safety

All our storage platforms and mezzanines meet the formal requirements in terms of health and safety, fire protection. and building regulations. Each mezzanine at the project preparation stage is meticulously verified in terms of the impact of static and dynamic loads occurring at the place of its use. The use of the highest quality steel and high production standards meant that our industrial storage mezzanines obtained the German TUV certificate confirming the professional construction of our mezzanines.

Certificates and standards that meet our products: ISO 9001: 2015 certificate number CH16 / 1079 – Designing, manufacturing and safe of shelving equipment and wire production

PN-EN 1993-1-3: 2008 and PN-EN 1993-1-1: 2006 – Eurocode 3 Design of steel structures

Full service

Please contact us for individual pricing and design. If you have any questions, please contact our sales department who will answer all your questions.

Installation

All our mezzanine floors are installed by professional assembly teams with many years of experience. This guarantees safety and quality of workmanship. A large implementation team means that we are able to quickly assemble large and complex structures in the customer’s facility.

Storage mezzanine during assembly

Transport

We organize transport of warehouse mezzanines to any place in Poland and the EU.

Financing

We provide attractive financing of warehouse mezzanines in the form of leasing. You do not need your own funds to finance the investment.

Frequent asked question

Mezzanine floors allow for convenient storage of various products on several levels, giving them very easy access. They increase the available storage space several times and can be easily adapted to the current needs of use. The biggest advantage of the mezzanine is the floor, which shelves do not have. Thanks to the mezzanine floor, you can stand next to each rack, gain access to all shelves at your fingertips and visually check what goods are stored and their quantity.

Almost everything can be stored on the mezzanine, based on the selected configuration of the supporting structure. For example, we can use the entire structure on shelf racks, or equip it with racks and traverses for storing pallets and loose / oversized products.

Yes, it is possible thanks to the addition of mezzanine profiles to the existing frames. The best redevelopment scenario is when the current storage racks are spaced at equal intervals of multiples of 100 mm. Thanks to this, we do not have to personalize certain elements of the mezzanine, which reduces the overall cost. Such elements include, among others: the floor and railings.

The extension of the mezzanine is always possible and if we want to increase its dimensions, it is not technically difficult. The mere change of equipment, such as replacing the shelves with crossbeams, or cabinets, etc., is also possible. The only obstacle in the reconstruction of the mezzanine are the construction beams, which should be replaced with new, longer ones.

It depends on what products are to be stored. For example, if you plan to store only pallets, then pallet racking is a better solution due to the higher load capacity and lower price. Mezzanines are better when you plan to store large amounts of general cargo, or to mix types of storage (pallet with loose). The mezzanine is recommended when we want to visually inspect the goods. Also in the case of manual confectioning, the only available solution is to use a storage mezzanine.

The basis of the warehouse mezzanine are racks (shelf or pallet) on profiles, while the base of the warehouse platform are only pillars – which in this case gives a free space for storage on the zero level.

The prices of warehouse mezzanines start from less than PLN 1000 / m2 with a large area, low complexity of the structure and low required load capacity of the floor. The number of storeys, the required load capacity, the type of construction required and, to a lesser extent, the accessories used have a huge impact on the price of the mezzanine. As each mezzanine is different, as it is designed for the specific and individual needs of the client, their offered prices may vary significantly.

It depends on the size of the mezzanine, on average the assembly takes about a week.

In the storage mezzanine, it is recommended to use an additional lighting installation. Even if we use a perforated floor, the amount of light reaching the lower floors will be insufficient to view the goods.

In the meaning of the Building Law, the mezzanine is not a story if its area is smaller than the area on which it is placed.

In a practical sense, the mezzanine is undoubtedly an additional usable space. On the other hand, in the legal (e.g. tax) sense, the positions of courts and institutions are divided. You can come across various interpretations of applicable regulations and interpretation of storage mezzanines as additional usable space, as well as such that they do not constitute such space.